Welcome to leathershoetech.com!

Welcome to leathershoetech.com!

Quzhou Wimbo Imports & Exports Trading Co., Ltd.

Quick Details

Packaging & Delivery

| Quantity(Prices) |

| Est.Time(days) |

Two station TR shoe sole machine, injection moulding machine MAIN GROUP manufacturer

WITH 35 YEARS OF EXPERIENCE IN THE FIELD OF STATIC MACHINES, AND NEARLY 5000 UNITS SOLD IN THE WORLD, GLOBAL BS/150 IS THE RESULT OF A SUCCESSFUL RESEARCH AIMED AT THE COST PRODUCTION AND MARKETING ORIENTATION. GLOBAL BS/150 MAINLY INCLUDES TWO TYPES EXTRUDER AND SCREW-PISTON, FOR THE PRODUCTION OF ONE OR TWO COLORED SOLES IN ALL KINDS OF THERMOPLASTIC MATERIALS(TR, TPR, PVC, TPU).

| Technical Terms | Unit | Extruder | Screw-piston | ||

| Mould-holder | |||||

| Mould-holder | N. | 2 | |||

| Mould Clamping force | ton | 150 | |||

| Mould Openging Stroke | mm | Max.370 | |||

| Mould Thickness | mm | Max.120 | |||

| Max.mould Size | mm | 480x550 | 480x550 | ||

| Injection Unit | |||||

| Number Of Extruder | N. | 4 | |||

| Number Of Injectors | N. | 4 | |||

| Screw Diameter | mm | 66 | 65 | 55 | 45 |

| Screw Speed | r.p.m | 226 | 160 | 130 | 160 |

| Injection Volume | cc | 750 | 1000 | 720 | 480 |

| Plasticizing Capacity | Kg/h | 45 | 100 | ||

| Power Installed | |||||

| Total Installed Power | kW | kW | 76.38 | 46 | |

| Average Consumption | |||||

| Electrical Energy | kWh | 8 | 15 | ||

| Air | NL/min | 200 | |||

| Refrigeration Units | Frig/h | 12000 | |||

| Weight | |||||

| Net Weight | Kg | 6500 | 6700 | ||

| Dimension | |||||

| length | mm | 2200 | |||

| width | mm | 2700 | |||

| height | mm | 2600 | |||

AUXILIARY MATERIALS FOR CHOICES

Soles products which was made by our Automatic TR injection moulding machine :

1. The movement mechanism is under the gear transmission computer digital control , stable in movementand accurate in positioning .

2. The mould clamping and locking mechanism is in aunique structure format, with greater mold clamping and locking force, for a nice appearance of products without flashes and burrs.

3. The mold rolling mechanism is safe and reliable, easy to remove and change a mold, with a large space for operation .

4. In a reasonable design , easy to install , small vol.and space .

5. Compliant with humanize design , easy to operate, automatic molding opening & closing, saving labour cost .

6. Adopting intelligent man-machine interface and PLC program comtrol, with precise measurement .

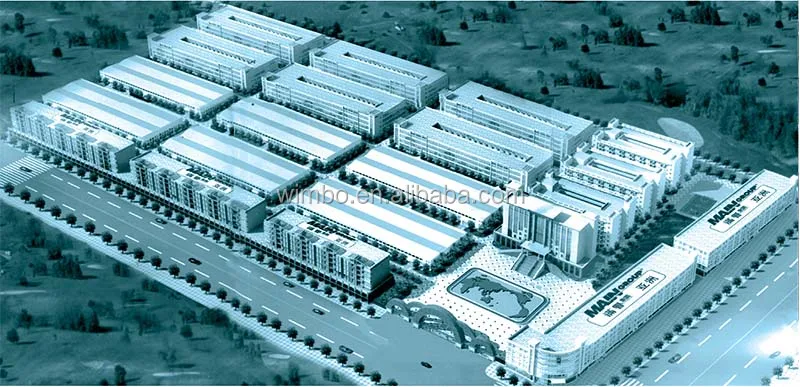

MAIN GROUP has been in all leading position in the field of injection molding machine for the world foot wear industry. with more than 80 years' industry experiences, MAIN GROUP has manufactured more than 14,000 machines.which have been sold to customers all over the worId.

We have various types of machines to satisfy the multi-level demand of different users, including advanced high technolgy processing equipments as well as simple-structure, user-friendly,economical and applicable machines These equipments can be used for the injection of thermoplastic materials, polyurethane, rubber, EVA and other compound materials.

In order to better serve the market and customers, MAIN GROUP Technology(Italy)set up MAIN GROUP(Fujian)Foot wear Ma- chinery Co.Ltd. in Jinjiang,Fujian in early 2004,namely MAIN GROUP Asia. MAIN GROUP Asia always adheres to the philosophy of quality first. leading technology,energy conservation and environmental protection,continuously innovates new machines in accordance with market demand,and provides perfect service.