Welcome to leathershoetech.com!

Welcome to leathershoetech.com!

>=1 Pieces

$5000.0

Model Number

Customization:

Payments:

Qingdao Jiuzhou Jucai Machine Co., Ltd.

Quick Details

Packaging & Delivery

| Quantity(Prices) |

| Est.Time(days) |

we provide a wide range of rubber injection molding machine for various kinds of application and production capacity

Mold closing force : 25T , 50T , 80T,100T,120T,160T,200T,250T,300T,350T,400T

Hydraulic part : Yukend Brand , Park Brand

Electrical cabinet : PLC SIMENS Brand , sometimes PLC from Taiwan Technology

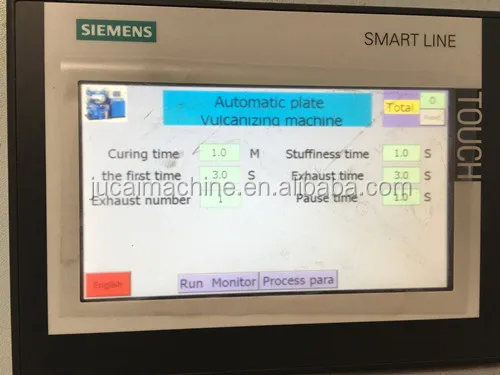

SIMENS BRAND PLC TOUCHING SCREEN CONTROL YULEND BRAND HYDRAULIC VALVE

Applicable for various rubber moulding production

PLC control & touch screen

Auto mold closing, air exhaust, temperature control, timing setting

Custom mold push out system

Well-sealed hydraulic cylinder with precise grinding and finishing

Stable hydraulic pressure station

1.This machine adopts the advanced PLC controller together with touching screen , which makes the machine easy operation and repair.

2.The machine adopts the imported high pressure vane pump and Proportional combination valve pressure flow, so it has reasonale design and good stability , little noise , small consumption.

3.The mold speed is felixable at vairous stages. At the beginning of mold closing , it owns the fast speed while when it will reach the top mold , the speed will be reduced to avoid the damage maybe caused due to high speed . After finish vulcanization , the mold opening speed will be faster to save the time to enhance the working efficiency .Meanwhile the product made by this machie has good quality with little waste edges .

4.This machine is suitable for various kinds of rubber molded products

5.The machine can be equipped with 2RT/3RT/4RT devices for easy operation

Model | 100 T | 200 T | 300 T |

mold clamping force | 100 ton | 200 ton | 300 ton |

stroke | 300mm | 300mm | 300mm |

plate size | 450*500mm | 500*560mm | 600*600mm |

motor | 7.5kw | 11kw | 11kw |

heating power | 9.5kw | 10.8kw | 15.5kw |

cylinder diameter | 260mm | 320mm | 360mm |

machine weight | 6000 kg | 7000kg | 9000kg |

1.The machine adopts the world advanced UG software and PO0-E3D analysis aided design to integrally cast and form the optimal design of high rigidity , tight structure and long life service

2.Heating Plate is made of deep hole processing , after carburizing process,by using the principle of heat flux,high precision , and the advantage temperature analysis of optimal design

3.Use computer CNC processing to ensure the optimal precision of design

4.Japanese technology planar average pressure correction with a highest precision up to 0.2mm

5.Heating plate/ in-and-out template adopts carburizing treatment and is completed by grinding and nitriding , long wearproof,not easy to be deformed and high planar precision

1.Vacuum and plate vulcanizing series machine adopts double motors , double oil pumps, double coolers , double oil systems .

2.Unique oil circuit design with no shock and low noise during oil circuit operation to improve efficiency and reduce energy consumption

3.Unique design of high speed circuit makes slow mode locking switch stable and adjustable to adapt to different types of model

4.Oil seals from Japan in the whole plant and special oil-proof design have no oil leakage and good durability. split type fast vacuum system is faster in vacuum pump with higher rate of finished products

5.The oil circuit system has special design with no vibration , good stability , and is faster than similar machines when in-and out mold goes up and down

1.The machine adopts the original Japan or Germany PLC controller , concise and clear wire connection , stable and reliable operation , low fault rate

2.Full computerized monitoring function , user-friendly concept programming design , easy lively input interface , real time display system

3.Professionally design PLC output contact protection circuit board to make its internal total electric contacts work within DC5V 5mA ; Electromagnetism all adopts no site switch DC24V safe electric furnace control to ensure the control system stable and lasting

4.Electrical element adopts international standardized configuration which permanently avoid customers worries

1. Introduce the latest foreign digital style test high-end technology,provide higher thermodynamic property and better quality stability than traditional design

2.Electric heating , automatic short circuit current detection system breaks the circuit of electric heating temperature system and gives an automatic alert . when it has problem

3.Automatic temperature curve record , temperature control is a continuous prompt , by which improves the machine operation quality

4.Using Japanese famous brand digital temperature controller , it can control scale vein output , PID adjustable , precise humidity operation , so that the temperature is controlled 2C . The program has one week preview function

1.we will one year guarantee for the machine . During this period if there is anything wrong with machine , supplier are responsible for it and should offer the best spare part freely for buyer

2.supplier should send professional if required by customer

3.we will offer service for whole life of machine

In terms of leading technology , base on the principle of gradual and orderly progress , strengthen independently design , core manufacturing , continuous innovation key elements of enterprise development, maintain its leading position in technology

Develop the short and medium and long term and R&D program of new products , remain the industry leader position by using the time difference , to cope with the firece competition market . Strengthen persona;ized design , meet the individual needs of different cutsomers

we committed to research and innovation hydraulic machine equipment over a long period of time , in recent years , annual investment in R&D costs account for 10% of total revenue . we always continue to innovative , combine domestic and foreign professionals , universities , research institute to cooperate .

System service , will be the most timely and most reasonable , efficient and quick to maintain customer service , so that the customers interest can be achieved . Powerful and perfects service team , timely and effective manner and dedication to customer service

we have strong technical elite , whether customers encounter any machine problems , we always will be the first time to deal with , if encounter with difficult problems , such as special security occurs , our strong technical team , will be the first time to discuss a solution and solve the problems for customer

Company video and photos

| Business Type | Manufacturer | Main Products | rubber vulcanizing machine,rubber mixing machine,rubber injection machine,rubber extruder,rubber kneader |

| Total Employees | 11 - 50 People | Year Established | 2017 |

| Total Annual Revenue | US$2.5 Million - US$5 Million | ||

| Certifications | -- | Product Certifications | CE,CE,CE |

| Trademarks | -- | Patents | -- |