Welcome to leathershoetech.com!

Welcome to leathershoetech.com!

>=1 Pieces

$4800.0

Model Number

Power

Customization:

Payments:

Gongyi Xiaoyi Hongying Machinery Factory

Quick Details

Packaging & Delivery

| Quantity(Prices) |

| Est.Time(days) |

| Product Parameter | ||

| Dimension | Weight | Voltage |

| 1300×1780×2020(mm) | 1.2t | 380V |

| Daily Capacity | |||

| Block size(mm) | Number of single molding | Molding Cycle | Production/8 Hours |

| 390*190*190 | 4 blocks | 35s | 3300 blocks |

| 400*150*200 | 5 blocks | 35s | 4100 blocks |

| 400*120*200 | 7 blocks | 35s | 5800 blocks |

| 400*100*200 | 6 blocks | 35s | 5000 blocks |

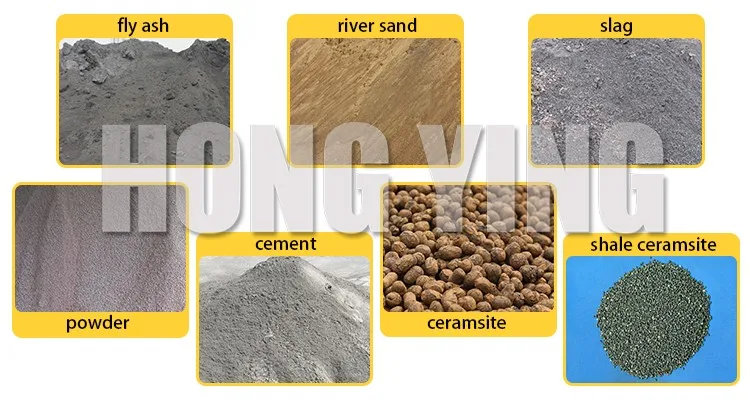

Block Raw Material:

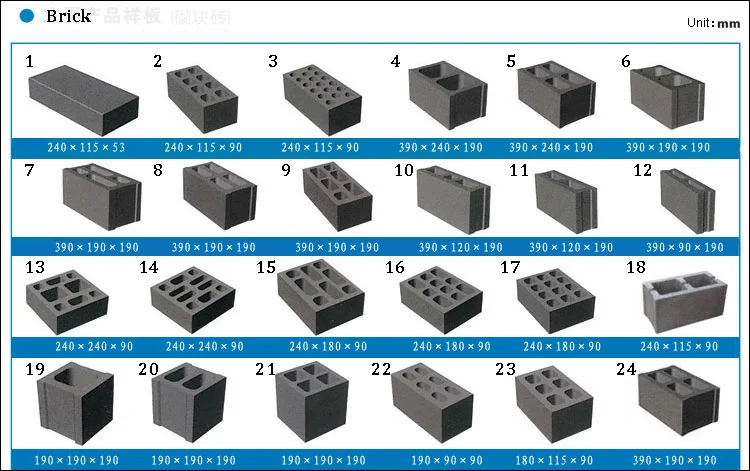

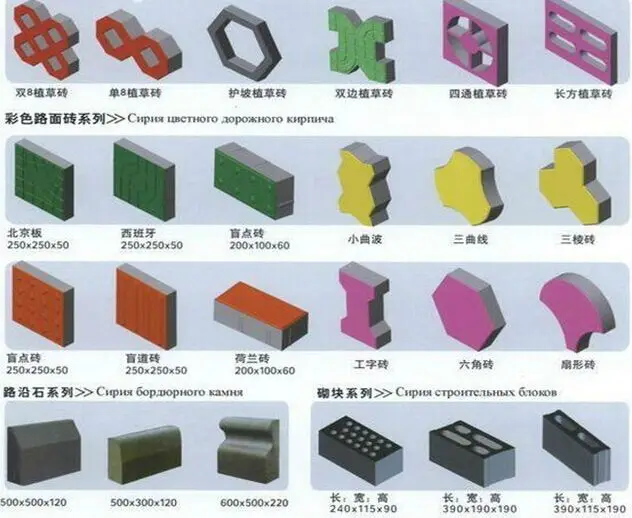

Block Types

(Tell us the block number, or we can customize according to your requirements.)

Production Condition

1. The machine needs to work in a flat site; pallet about 500-1000 blocks (850 x 550 x 30 mm), and the pallet must be kept in a same height.

Production of block maintenance

A: When the outdoor temperature at 20 -30 ℃, natural maintenance 3-4 hours can be covered, watering, maintenance. 24 hours stacking.

B: When the temperature is too low, two days it can be stacking and this process should be lasts 7 days

C: When it is sunny, it should be watered every 2 hours. Be careful with the stack so as not to damage it

Features

1. QTJ4-40B Fly ash blocks moulding machinery / fly ash concrete brick forming machine / fly ash block productin line use four columns oriented, equipment with vibrating motor. During working time, the vibration table and upside pressure head vertically vibrate synchronously, make the flow of raw materials filled dense.

2. Machine’s body is made from profiles, strong earthquake resistance, and suspension use the “spring vibration isolation” and directional vertical vibration technology to reduce power consumption as well as loss of mold.

3. Timing vibration, automatically lift mold.

4. The pressure head is longitudinal traverse for convenient to feeding, maintaining and washing.

5. The plate vibrate with mold box synchronously, without impact force and extend service life.

6. Multi–usage, replacing the mold can produce the block with various specifications. Easy operation and convenient.

Production Flow chart:

Related products

| Related Products ( Click bellowing different models to get more choice ) | |||||||

| Model and Video | Photo | KW | Pcs/cycle | Forming cycle(S) | Capacity(pcs/h) | Pcs/8hours | Operation type |

|

|

|

||||||

| QMY4-40 | |||||||

| QMJ4-35A | |||||||

| QTJ4-40B | |||||||

| HY150K | |||||||

| QT3-15 | |||||||

| QT5-20 | |||||||

Videos

| Brick making machine working Videos ( Copy and stick the video link on browser ) | |

| QMY2-40 | https://www.youtube.com/watch?v=ebeh5mpZPH8 |

| QMY4-40 | https://www.youtube.com/watch?v=3VhuTSrLt_k |

| QMJ4-35A | https://www.youtube.com/watch?v=eOn6lh51mfY |

| QMJ4-35C | https://www.youtube.com/watch?v=yDdtaITrGEU |

| HY150K | https://www.youtube.com/watch?v=8-Kgaz4y9no |

| QT3-15 | https://www.youtube.com/watch?v=zx6Fv7Q_vDc |

| QT5-20 | https://www.youtube.com/watch?v=cKt6JTv_KIU |

We also can provide clay brick , Interlocking brick, Concrete block and Paver machine

You can also directly visit our website http://gyxyhy.en.alibaba.com to find more details.

Packaging details:

1.Standard export packing or according to customer's requirements

2.use crane/forklist to load the machines into the container

3.use the wire to fasten the machines in order to keep them stable

4.use the cork wood forbid collision

Shipping Detail :

Swift delivery , within 10 days after receiving the deposit.

Hongying machinery factory, located in Gongyi, Henan province, specialized in brick, food and construction machinery for over 15 years, we have rich experience and enjoy good reputation in China and foreign market. Since our establishment, we have regarded quality as the most important and eternal principle in production. Our products include brick making machine, road tile machine, clay brick making machine, hydraulic press, oil press,etc.

Company video and photos

| Business Type | Manufacturer, Trading Company | Main Products | Cement Block Making Machine,Clay Brick Making Machine,Concrete Mixer,Crusher Machine |

| Total Employees | 51 - 100 People | Year Established | 2006 |

| Ownership | Private Owner | Total Annual Revenue | confidential |

| Certifications | -- | Product Certifications | -- |

| Trademarks | Hongying | Patents | -- |

Production Flow

| machineName | yearsUsed | brandModel | quantity | condition | verified |

|---|---|---|---|---|---|

| Planer | 0 | Confidential | 1 | Acceptable | |

| Steel Plate Shearer | 0 | Confidential | 1 | Acceptable | |

| Plasma Cutting Machine | 0 | Confidential | 1 | Acceptable | |

| Lathe Machine | 0 | Confidential | 1 | Acceptable | |

| Drilling Machine | 0 | Confidential | 1 | Acceptable | |

| Milling Machine | 0 | Confidential | 1 | Acceptable | |

| Boring Machine | 0 | Confidential | 1 | Acceptable |