Welcome to leathershoetech.com!

Welcome to leathershoetech.com!

Nanjing KERKE Extrusion Equipment Co., Ltd.

Quick Details

Packaging & Delivery

| Quantity(Prices) |

| Est.Time(days) |

Plastic Two stage compounding extruder pelletizing machine system

Paraments

Model | D (mm) | L/D | N (r/min) | P (KW) | Q (kg/h) | |

KTE-16A | 15.6 | 28~40 | 600 | 1.1/2.2 | 2~10 | |

KTE-20A | 21.7 | 28~40 | 600 | 3/4 | 3~15 | |

KTE-36 | A | 35.6 | 28~52 | 500 | 11/15 | 20~60 |

B | 35.6 | 28~60 | 500/600 | 18.5/22 | 20~100 | |

KTE-50 | A | 50.5 | 28~60 | 500 | 45 / 55 / 75 | 80~150 |

B | 50.5 | 28~60 | 400/500/600 | 45/55/75 | 120~280 | |

KTE-52B | 51.4 | 28~60 | 400/500/600 | 45/55/75 | 120~280 | |

KTE-65 | A | 62.4 | 28~60 | 500 / 600 | 55 / 75 / 90 | 150~380 |

B | 62.4 | 28~60 | 400/500/600 | 90/110 | 200~500 | |

KTE-75 | A | 71 | 28~60 | 500 / 600 | 90 /110 /132 | 300~550 |

B | 71 | 28~60 | 400/500/600 | 110/132/160 | 300~800 | |

KTE-85B | 81 | 28~60 | 400/500/600/ | 160/220/280 | 480~1000 | |

KTE-95B | 93 | 28~60 | 400 / 500/600 | 250 /280/ 315 | 750~1400 | |

Representative materials working capability schedule of KTE-series same-direction parallel twin screw extruder

KTE series twin-screw extruder | |

Mixing modification | PE,PP,PS+SBS,PA+EPDM,PP+NBR,NVA+silicon rubber,etc |

PE,PA,PC,CPE+ABS(ALLOY),ABS+TPU,PBT+PET,PE+PP,etc | |

Filling modification | PE,PP,EVA,etc+Calcium carbonate,talcum power,titanic powder |

ABS,PC,PS,etc+aluminum hydroxide,magnesium hydroxide,antimony oxide | |

PP,PA,ABS+ferrous powder,sulphuric powder,ceramic powder | |

Functional masterbatch | PP,PA,ABS,PBT,etc+burning agent and other auxiliary agents: combustion-supporting machine pellets |

PP,PE,PS etc+starch: de-composing machine pellets | |

PE+fog-preventing dipper,stabilizer: dual-prevention machine pellets | |

PE,EVA,ABS+carbon black:black machine pellets | |

Colored masterbatch | PE,PP,ABS,AS,PA,EVA,PET+pigment and auxiliary |

glass fibers/ carbon fibers reinforcement | PP,PBT,ABS,AS,PA,PC,POM,PPS,PET,etc+long fibers ,small fibers,carbon fibers,crystals and so on |

Various cables | HDPE,LDPF,LLDPE,MDPE,EVA,PVCetc+Insulating cables, coatings,PE peroxide,silicon alkyl crossing cables |

Special materials | EVA heat-melting glue,polyurethane,fluorin rubber,fluorin plastics, PP cigarette filtering material and TPR sole material |

Reaction extruding | Polyamide condensate,polyamide melting polymerization, polyamide polyethrne-adding,polycarbonate condensate,etc |

Exhausting and Volatilization | Polystyrene oxide,high-absorbing resin,chlorine sulphur polyethylene |

Powder paint | Polyester,ring oxide,lactide,polyurethane,acrylate |

Configuration

1.Twin screw Volumetric feeder

2.Reduction gearbox

3.Lubrication oil cooling system

4.Motor of host machine

5.Screw and charging barrel

6.Heating system

7.Vacuum degasification device

8.Soft water cyclic system

9.Screen changer system

10.Auxiliary machine

11.Electrical control cabinet

Screw & Barrel

The screw elements are designed accuratly and made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heater treatment.

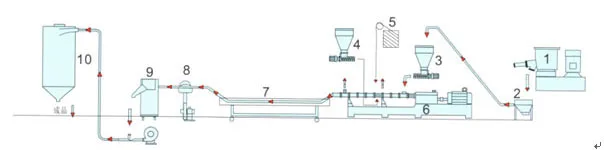

water-cooling strands pelletizer

1. high-sped mixer 2. solids-conveyer 3. main feeder 4. side feeder 5. glass fiber

6.twin-screw extruder 7. water trough 8.air-knife 9. pelletizer 10. product container

Application:

1.Fiber reinforcement: glass fiber, carbon fiber reinforced PP,PA,PBT,ABS,AS,PC,POM,PPS,PET,

PPO,PSF,LCP,etc.

2.Ploymer blending :bleding of PC+ABS, PA+ABS,CPE+ABS,PP+EPDM,PA+SBS,etc.

3.Incorporation of fillers :CaCO3,Tale,TiO2,carbon black filled PE,PP,or EVA etc.

4.Cable Compounds:cable sheath,cable insulation compounds of LDPE,HDPE,LLDPE,MDPE;radiation-crosslinkable compounds ,optical fiber protection compounds ,heat-shrinkable polymer compounds.

5.Special Compounds :PPR pipe compounds,PE compounds for crosslinked pipes,tobacco filter

compounds,etc

6.High Concentration Color Masterbatches: PE,ABS,PS,EVA,PET,PP etc. With high concentration of pigments and other procrssing aids.

7.Masterbatches with Flame Retardants:PP,PA,ABS,EVA,PBT etc.with flame retardants and other

additives.

8.Special Functional Masterbatches :Masterbatches with anti-static,anti-abcteria ,or other

special functional fillers.

9.Masterbatches for Degradable Polymers:PP,PE,PS etc. Blended with high concentration of

starch and other processing aids.

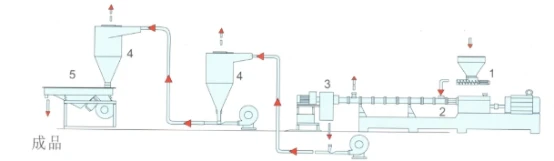

Air-cooling hot-face pelletizer

1. metering feeder 2. twin-crew extruder 3. ari-cooling hot-face pelletizer

4.cyclone 5.vibrating sleve

Application :

Enforcing modification PE,EVA etc.+CaCO3 ,talc,TiO2,carbon black.

Degradable master batch:PE,PS etc. + starch,additive etc.

Anti-flame master batch :PE,EVA etc. +Sb2O3,Mg(OH)3 etc.

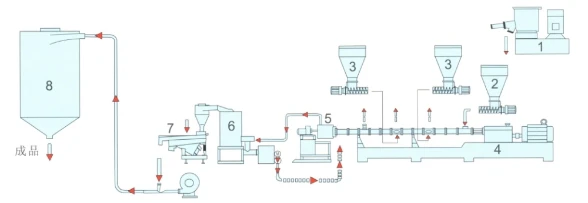

water-ring hot-face pelletizer

1.high-speed mixer 2. main feeder 3. side feeder 4. twin-screw extruder 5. water trouh

6.centrifugal off-water machinery 7.vibrating sieve 8. product containeraa

Application:

1.PE,EVA etc. ,filled with CaCO3,talc,TiO2,carbon black etc.

2.Cable sheath , cable insulation compounds of LDPE,HDPE,LLDPE,or MDPE;

3.PPR pipe compounds,PE compounds for crosslinked pipes;

4.TPR,TPU TPV thermoplastic elastomers; EVA and hot-melt adhesives

5.Color concentrates of PE,ABS,PS,EVA etc;

6.Flame retardant masterbatcher of ABS,EVA etc;

7.Masterbatches with PE,PP,PS etc. As carriers for degradation applications.

Prouduct is packed by plastic film or wooden case and shipping by sea.

Presales service:

>introducing in detail features and application of the products to customer

>Selecting economical and practical machine & equipment for customer

>Providing operation data of the related machine & equipment

>Providing means of trial performance for customer

Sales service:

>Recommending engineering conditions required for installation of the machine & equipment

>Communicating in time the manufacturing progress of the machine with user

>Providing assistance in technical conditions, screw combination and barrel disposition needed for product

After-sales service:

>Providing on-the-spot technical assistance in installation, commission and training

>Filling in detail customer’s information

>Providing long-term maintenance service and spare parts

>Giving technical support to customer for developing new product

>Providing free maintenance for a year

Our workshop

Automation equipment & Strong technical team

Contact me !

1. Q: Are you a factory or trading company?

----A: Both

2.Q: How long is the guarantee?

A: 1 year after the machines arrive in customer's factory.

3. Q: Where is your factory located? How can I visit there?

-----A: Our factory is located in Nanjing, Jiangsu Province, China,

1) You can fly to Nanjing Airport directly. We will pick you up on Nanjing Lukou International airport;

2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed railway, then we will pick you up in the railway station.

All our clients, from domestic or abroad, are warmly welcome to visit us!

4.Q: What makes you different with others?

----A: 1) Our Excellent Service

For a quick, no hassle quote just send email to us

We promise to reply with a price within 24 hours - sometimes even within the hour.

If you need an advice, just call our export office at +86 025 84938824, we will answer your questions immediately.

2) Our quick manufacturing time

For Normal orders, we will promise to produce within 30 working days.

As a manufacturer, we can ensure the delivery time according to the formal contract.

5.Q: How about the delivery time?

----A: This depends on the product. Typically standard products are delivered within 30 days.

The delivery time of the special products is according to the time of setting up of the tooling.

6. Q: What is the term of payment?

----A: 1) T/T payment; 2) LC;

7.Q: May I know the status of my order?

----A: Yes .We will send you information and photos at different production stage of your order. You will get the latest information in time.

Company video and photos

| Business Type | Manufacturer, Trading Company | Main Products | Extruder Screw And Barrel,Twin Screw Extruder / Single Screw Extruder / Pelletizing Extruder / Extruder Screw And Barrel |

| Total Employees | 51 - 100 People | Year Established | 2009 |

| Ownership | Private Owner | Total Annual Revenue | confidential |

| Certifications | -- | Product Certifications | CE,CE,CE |

| Trademarks | -- | Patents | -- |

Production Flow

| machineName | yearsUsed | brandModel | quantity | condition | verified |

|---|---|---|---|---|---|

| Cutting Machine | 2 | Confidential | 1 | Acceptable | |

| Bending Machine | 2 | Confidential | 1 | Acceptable | |

| Drilling Machine | 2 | Confidential | 3 | Acceptable | |

| Milling Machine | 2 | Confidential | 1 | Acceptable | |

| Grinding Machine | 2 | Confidential | 1 | Acceptable | |

| Lathe | 2 | Confidential | 1 | Acceptable |