Welcome to leathershoetech.com!

Welcome to leathershoetech.com!

Hefei Moretech Machinery & Mould Co., Ltd.

Quick Details

Packaging & Delivery

| Quantity(Prices) |

| Est.Time(days) |

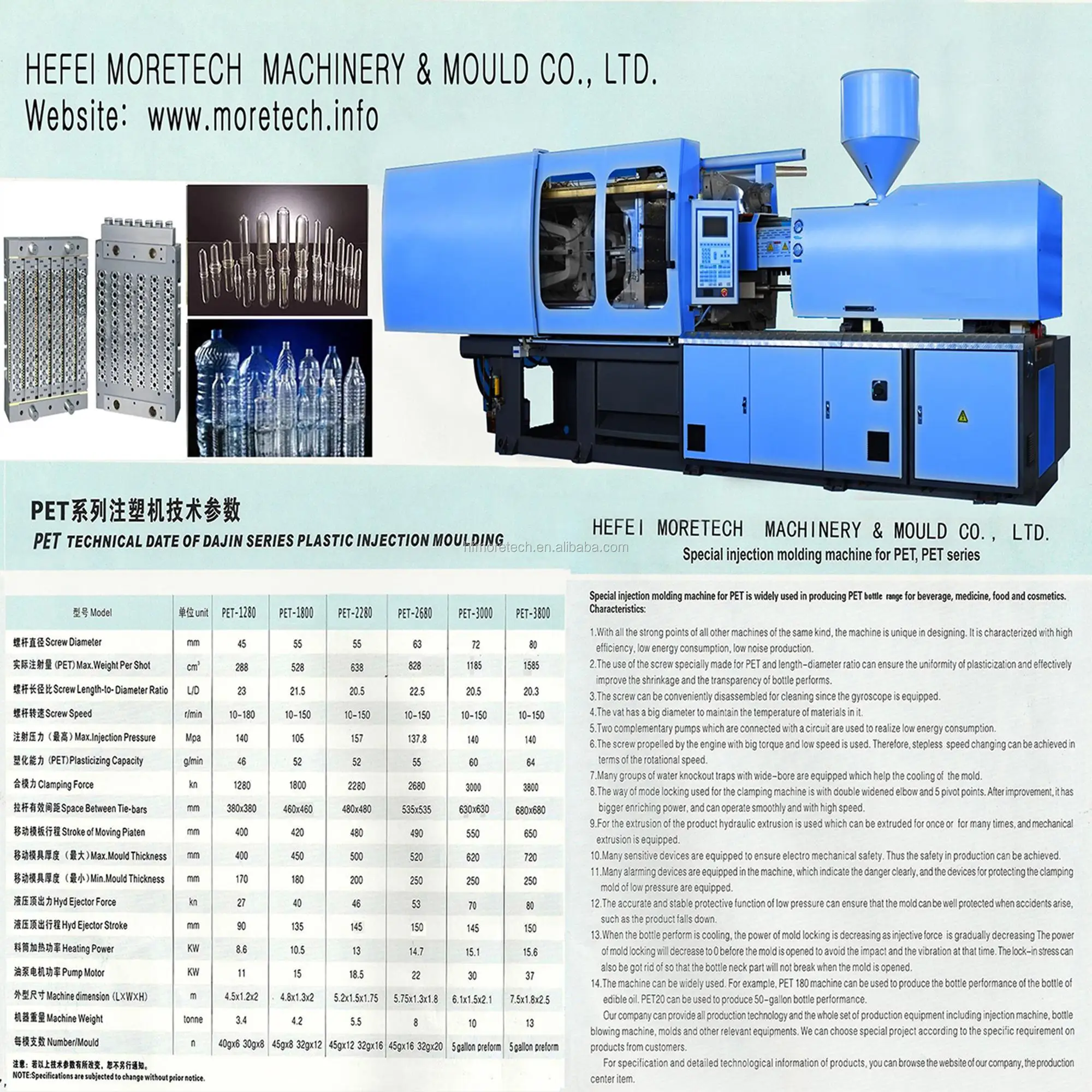

HL / PET Serises high energy-saving machine

HL produces high energy-saving machine from the model HL-500 to HL- 9800. PET-1280 to PET-3800 The standard high speed injection molding machines are equipped with accumulator to realize the high speed turning of the screw. The optional for high speed mould close and mould open are also available. Our high energy-saving machine has the special design for the machine's base, machine's frame and especially the clamping system. In the past several years' international fair, our high speed injection moulding machines are always displayed. The high speed, precision injection... all these have got the high praise from all the visitors.

1.Absorb pulsations of energy from the multi-piston pump:

It also helps protect the system from fluid hammer. This protects system components, particularly pipe work, from both potentially destructive forces. An additional benefit is the additional energy that can be stored while the pump is subject to low demand. These are often placed close to the demand to help overcome restrictions and drag from long pipework runs.

An accumulator can maintain the pressure in a system for periods when there are slight leaks without the pump being cycled on and off constantly. When temperature changes cause pressure excursions the accumulator helps absorb them.

2. Low noise Hydraulic circuit high efficiency Injection:

Balanced and high speed mould clamping and opening precise temperature controlling Precise shot weight controlling outstanding energy saving with high return of investment

3. high energy-saving machine Clamping Unit

The new generation toggle mold locking device and computer emulation optimized toggle parameter makes motions of the moving plate fast and steady. When combining the box type moving plate, fixed plate and high rigidity toggle structure, the characteristic of high strength and anti-fatigue is secured. Compared with similar machines, it owns bigger internal spur between tie bars, mold space and mold opening stroke and may process plastic products of bigger size.

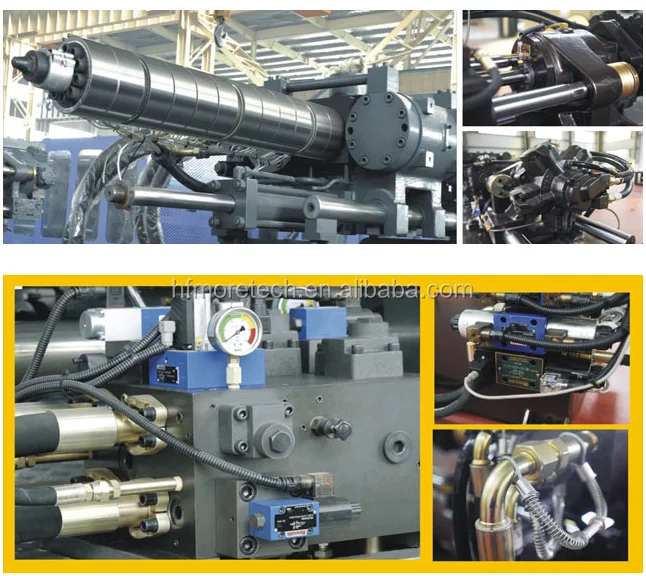

4. high energy-saving machine Hydraulic Unit

High efficiency, energy saving and high precise proportional pressure and flow variable displacement pump system makes the hydraulic system output match the required power for entire machine operation without high pressure throttle and overflow energy loss. Compared with constant displacement pump, it saves power by 30%-60%. A motor with same power may be fitted with an oil pump of bigger displacement and thus accelerate the machine speed. Besides, the low oil temperature will prolong the service life of sealing elements.

Use of imported high performance precise oil filter device will further prolong the normal operation of hydraulic system. Buffer device is used in every mold opening and clamping oil way to ensure steady mold opening and clamping operation without any impact. Besides, differential mold clamping operation is fitted to ensure high production efficiency.

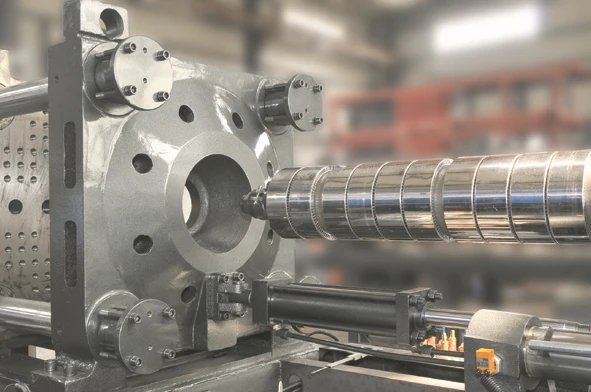

5.High speed injection moulding machine Injection Unit

Short and forceful double-cylinder injection system is used to ensure the stead injection motions. The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticating capacity and effect. The screw head and back stop ring made of Japanese high tenacity hot working tool steel by special heating treatment features high temperature resistance, wear endurance and hot burnout resistance, maintaining extremely high hardness during high temperature operation. The screw and material tube made of high-grade alloy steel by vacuum ion nitriding treatment feature high hardness, corrosion resistance and wear endurance.

PID temperature control in combination of high precision electronic ruler and control regulates the speed and pressure of injection, pressure keeping, smelting, back pressure and other motions to ensure the quality of formed products and continuation of production. Auto material preparation, drooling proof, and anti cold start lapse functions ensure the high efficient, simple and safe operations.

According you inquired injection machine, therefore we listeed injection machines with quotations below. Please reference attached photos and specification .

1. Injection moulding machine HL- 9800L 980 ton 1 set 145,500

Injection moulding machine HL- 7800L 780 ton 1set 86,800

Injection moulding machine HL- 5800L 580 ton 1set 58,500

Injection moulding machine HL- 4000L 400 ton 1set 37,500

Injection moulding machine HL- 3000L 300 ton 1set 27,500

Injection moulding machine HL- 2680L 268 ton 1set 25,800.

Injection moulding machine HL- 1800T 180 ton 1set 17,500.

Injection moulding machine HL- 1680L 168 ton 1 set 14,800.

00

00

Regarding PET preform injection machine quotations below :

Description Max.shoot Quantity Subtotal (USD)

1. Injection moulding machine PET-1280 ( 280gs making ) 1 set 11800

PET-1800 ( 520gs making ) 1 set 16800

PET-2280 ( 620gs making ) 1 set 21500

PET-2680 ( 720gs making ) 1 set 25800

PET-3000 ( 1050gs making ) 1 set 28500

PET-3800 ( 1400gs making ) 1 set 35800

Above Total Amount (FOB Ningbo ,china )USD only

You may according your request to choose some machine from above list .

Payment terms : Deposit 30% of Total amount by T/T , Remaining before shipment .

Delivery time : Within 10 days after we received the Deposit.

After-sales service terms: Installing time 7days ,Buyer will Garantee our Engineer's safety and bear international airticket and all charges overseas .

Warranty time & terms: One year under normal operation and environmental condition .

Pls tell me your product's production capacity even your budget , we'll provide you a satisfactory solution !

Your response will be highly appreciated !

Yours faithfully

Crediman Huang

HEFEI MORETECH MACHINERY & MOULD CO., LTD.

Website: www.moretech.info

WhatsApp: + 86 1300 3060 953

Company video and photos

| Business Type | Manufacturer | Main Products | Plastic injection moulding machine line,Plastic bottle blow moulding machine line,Plastic mould,PVC / PPR Pipe extruder machine line,Plastic recycling machine line |

| Total Employees | 51 - 100 People | Year Established | 2011 |

| Total Annual Revenue | Below US$1 Million | ||

| Certifications | -- | Product Certifications | CCC |

| Trademarks | plastic recycling machine special | Patents | -- |

Production Flow

| machineName | yearsUsed | brandModel | quantity | condition | verified |

|---|---|---|---|---|---|

| Machanical parts processing equipment | CNC Lathe /MIlling /Boring/Grinding/Drilling | 22 |