Welcome to leathershoetech.com!

Welcome to leathershoetech.com!

Guangzhou Jingyi Silicone Material Co., Ltd.

Quick Details

Packaging & Delivery

| Quantity(Prices) |

| Est.Time(days) |

rtv liquid silicone rubber for shoe sole molding

Specification:

1.plaster cementmould

2.For low melting alloys and pvc mould

3.For Sample mould.

4.For shoes mould

Features and Usage:

This series of product is made of special materials; it is the two-component condensed room-temperature curing liquid silicone rubbers. With low viscosity, sound fluidity, large adjustment range of hardness, low linear shrinkage rate, it can be widely used according to different purposes.

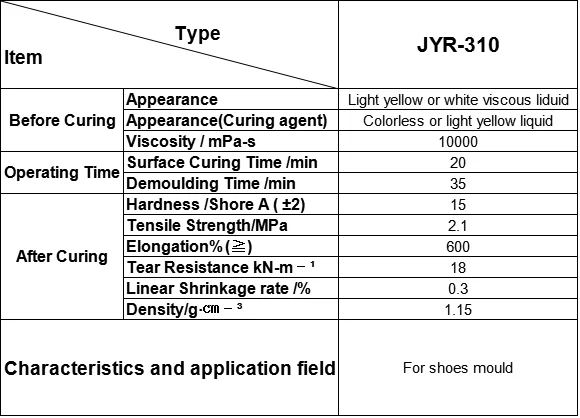

Main technical parameters:

1.To add 2-4% curing agent based on the weight ratio and currently mix and use it. It has to use it up in a short time.

2.Stirring the mixed rubber material and put it into the vacuum box for 3-5 minutes air extracting. The mold can be used after defoaming.

3.The curing rate of this product is closely relevant to the temperature. The higher the temperature is, the greater the humidity is and the curing speed becomes faster. Users can choose the curing agent according to the weather condition, and adjust the amount of the curing agent so as to reach the appropriated curing rate.

>>>Other hot sale mold making liquid silicone rubber type,please click the pictures of below

|

|

|

|

We can provide liquid additional cure silicone rubber with different hardness.

1. For small size and dttailed pattern(within 30cm), 15-20 shore A can be applied, which is easy for de-molding and will not damage the patterns.

2.For the products with medium size, such as 50cm, 25-30 shore A silicone rubber should be used.

3.For products with large size, such as 1m, 35-40 shore A shall be recommend to avoid deformation.

4.If the product is large but features detailed pattern, 30 shore A silicone rubber will be workable.(It will be better to protect the products from deformation to make outer mold.)

Note: All the above products hardness could be customized or adjusted according to customers' requirements.

Applications of liquid silicone rubber

Jingyi Silicone Material Co.ltd. is meanly produce: soap & candle mold silicone; RTV2 liquid silicone rubber for molding; plaster moulding gypsum decorative products mold making white silicone; medical grade skin color silicone liquid rubber for artificial human prosthesis like artifical finger; artificial penis silicone raw material rubber; 3D concrete bricks and Nordic style walll panels flexible molds; garden statues cement molding silicone; these room temperature silicon rubber are with different parameters for various materials of products, such as: polyurethane casting materials mold, high burn resistant resin products, scented stones, wax products, polyester , fimo pulp, paraffin, metal crafts, alloy, and food moulds,transparent insole, food grade nipple, epoxy product, fiber rein forced platic composite products recycling vaccum bag bagging making. There are two-componet, rapid molding liquid silicone rubber, with sound property of high and low temperature resistance,these molds can achieve the unshriking effect, and non-toxic and un pungent. It is of high transpancy and can endure hear to 300℃ -500℃ for our addition high temperature silicone rubber for molding.

1. This kind of rubber is packed in 25KG/iron drum and curing agent in 1L /plastic bottle

2.This product should be sealed and placed in cool place so as to prevent rain and sunlight exposure.

3.The storage period of this product is half a year. If it occurs to be more viscous, stir it and reuse it with the same property. It can be reused after reinspection when it exceed the storage period.

4.The surface of the replicative mold product such as glass, ceramics, resin, wooden ware or some product with coating should be smearred with surfactants (such as detergent, shampoo, soapsuds) . Perfuse or brush the silicone rubber after the water evaporates, which facilitates demoulding.

5.This product is nondangerous .During the operation, try to prevent any possibility of eyes and skin contact with the curing agent. Wash affected skin thoroughly with soap and water in case of touching it. Flush with clean running water immediately at least for 15 minutes, and consult a doctor if necessary.

FAQ

1. What’s silicone products you are making?

--liquid silicone, silicone rubber, silicone oil; Due to different silicone molds, our silicone has different viscosity, and cause different hardness, density to meet the requests from client.

2. Do you offer free sample to client?

--Yes, we can provide the sample for test.

3. How about the quality control in your factory?

--We have professional QC team to control the quality during production. Goods will be 100% inspected before shipment.

4. How to remove the bubbles during my mould making?

--After mixing liquid silicone with curing agent, please put the material into vacuum machine to take off the bubbles.

5. How to get good silicone mould to use longer time?

--The best way is:

1, Please choose the right liquid silicone according to your products.

2, Don’t use any silicone oil in mold making, because it can make the silicone mould become too soft to use.

3, Silicone mould can be used longer after the whole silicone mould fully cured, so it’s better to wait 2 hours after mould finished.

6. Why silicone rubber add curing agent after mixing a lot of bubbles?

--This is normal physical phenomena. The liquid will produce a large number of bubbles in the mixing time, so, it must pass through the vacuum exhaust bubble treatment.

For the further information, please feel free to contact :

Tel:+86-20-86299611

Cel:+86-13926009732

Whatsapp:+86-13926009732

Wechat:+86-13926009732

>>>Click here to email us & send inquiry

OEM SERVICE: A RAGE OF DESIGNS AVAILABLE, CLIENTS' DESIGNS ARE WELCOME

Company video and photos

| Business Type | Manufacturer, Trading Company, Distributor/Wholesaler | Main Products | General Silicone Rubber for Molding,Silicone Rubber for Molding with High Burn Resistance,Addition High Temperature Silicone Rubber for Molding,Silicone Rubber for Vacuum Bag Mould,Food -grade Silicone |

| Total Employees | 51 - 100 People | Year Established | 2012 |

| Total Annual Revenue | US$2.5 Million - US$5 Million | ||

| Certifications | -- | Product Certifications | Certification for Transport of Goods |

| Trademarks | -- | Patents | -- |