Welcome to leathershoetech.com!

Categories

Welcome to leathershoetech.com!

1-1 Pieces

$18000.0

>=2 Pieces

$15000.0

Power

Customization:

Payments:

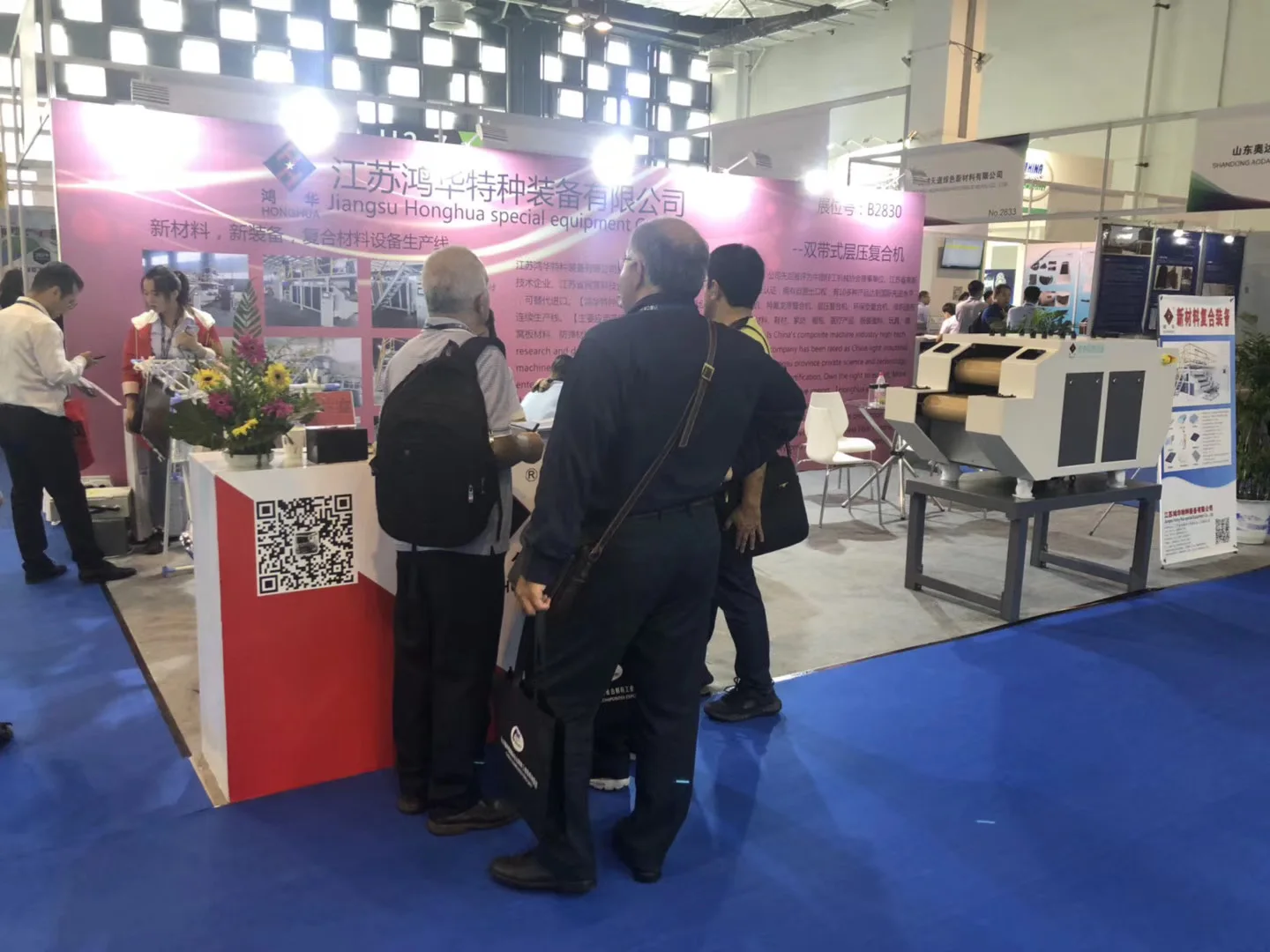

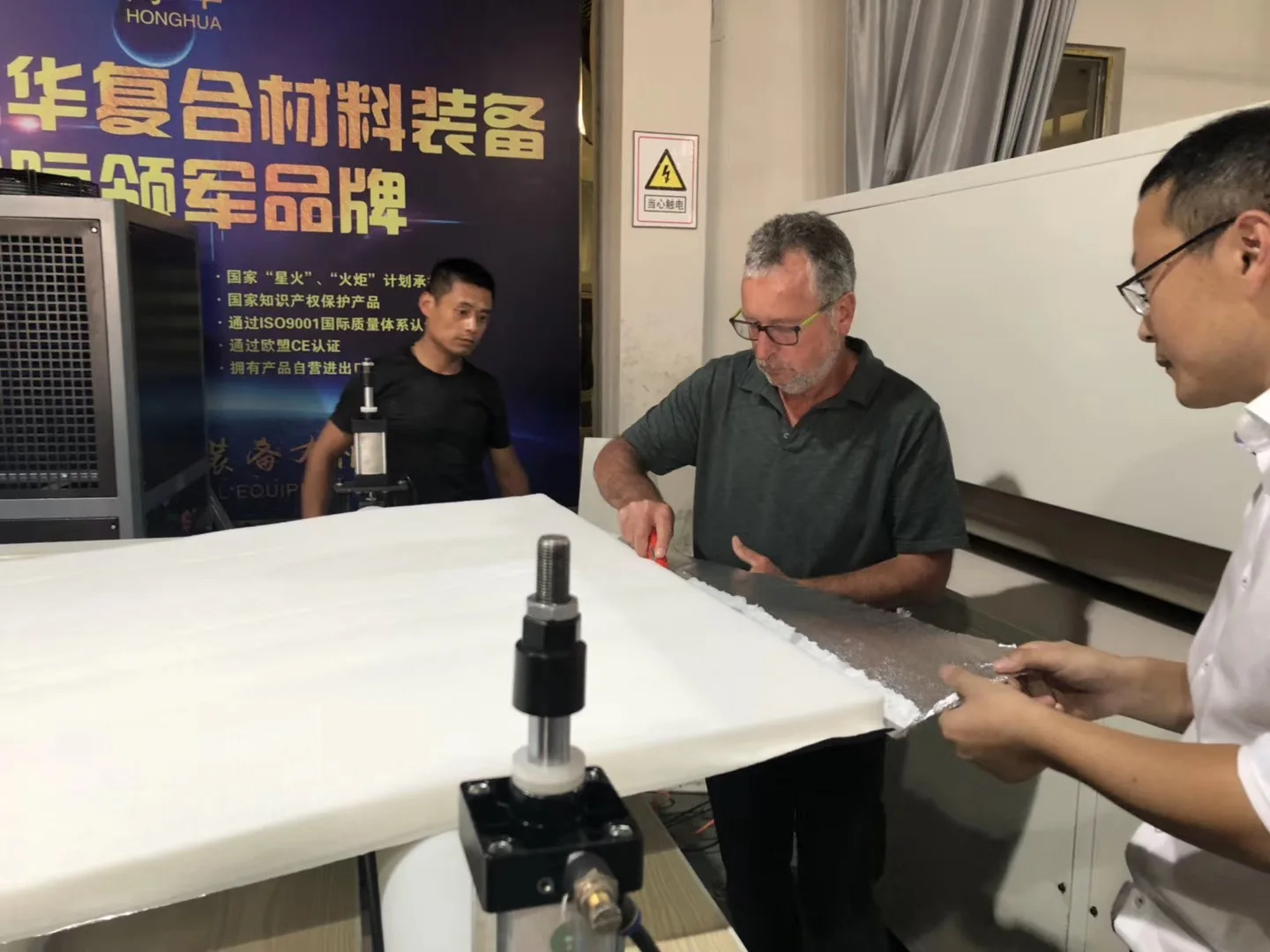

Jiangsu Honghua Special Equipment Co., Ltd.

Quick Details

Packaging & Delivery

| Quantity(Prices) |

| Est.Time(days) |

1. Power supply: 380V, 50HZ |

2. Generator power: 600W×12 |

3. Working frequency: 20KHZ |

4. Working speed: 0-1200M/H |

5. Continuous working time: less than 8 hours |

6. Working environment temperature: ≤28℃ |

7. Effective length of flower roller: 1850MM (can be customized according to user requirements) |

8. Flower roller diameter: ¢136MM |

9. Motor power: 2.2 KW +0.75KW |

10. Dimensions: 2500×2500×1550 (L×W×H) |

11. Weight: 3 |

12. Support various wide formats |

Company video and photos

| Business Type | Manufacturer, Trading Company | Main Products | laminating machine,coating machine,hydraulic cutting machine,four column cutting machine,compound machine |

| Total Employees | 51 - 100 People | Year Established | 2012 |

| Total Annual Revenue | US$5 Million - US$10 Million | ||

| Certifications | ISO9001 | Product Certifications | -- |

| Trademarks | -- | Patents | Camshaft signal wheel angle checking tool |

Production Flow

| machineName | yearsUsed | brandModel | quantity | condition | verified |

|---|---|---|---|---|---|

| CNC machining center | 1200 | 3 | |||

| Lathe | 6180 | 3 | |||

| CNC engraving machine | 2680 | 1 | |||

| Sawing machine | 500 | 4 | |||

| Drilling machine | 32 | 5 | |||

| Milling machine | 1250 | 2 | |||

| Planer | 1000 | 1 | |||

| Grinder | 1000 | 1 |