Welcome to leathershoetech.com!

Welcome to leathershoetech.com!

$20-$100

Model Number

Customization:

Payments:

Nanjing Cowin Extrusion Machinery Co., Ltd.

Quick Details

Packaging & Delivery

| Quantity(Prices) |

| Est.Time(days) |

Cowin has the original R&D team of under water pelletizing system in China. We focus on the latest technology innovation which helps our UW series to be high quality and more competitive.

1. Full automatic pneumatic knife feeding system to guarantee stable and continuous production. Cutting blade which contacts the die head can be adjusted automatically after abrasion, thus to guarantee the precise contact between cutter and die head. With PLC controlling system to meet manual/automatic operation, touch screen makes the operation and maintenance easily.

2. Super anti-wear hard alloy cutting blade with constant pneumatic cutting adjusting system to guarantee a longer life span.

3.Modular Designed Tempered Water Circulating System to meet different requirement from customers. Every part can be installed independently which makes it easier and faster to replace.

4. Based on requirements of customers as well as the characteristic of raw materials. COWIN EXTRUSION super anti-wear hard alloy die plate, cutting blades, high efficient and low energy consumption heading system make the cutting result more perfect.

Typical application areas are:

Thermoplastic elastomers: TPS, TPO, TPV (PP/EPDM ), TPU, TPE, TPA

Hot Melt Adhesive

Other areas: masterbatch, filling modification, polymer blending, fiber reinforcement

When the preferred pellet shape is more spherical than cylindrical, the best alternative is an underwater hot-face cutter. With a capacity range from about 20 lb/hr to several tons/hr, this system is applicable to all materials with thermoplastic behavior. In operation, the polymer melt is divided into a ring of strands that flow through an annular die into a cutting chamber flooded with process water. A rotating cutting head in the water stream cuts the polymer strands into pellets, which are immediately conveyed out of the cutting chamber. The pellets are transported as a slurry to the centrifugal dryer, where they are separated from water by the impact of rotating paddles. The dry pellets are discharged and delivered for subsequent processing. The water is filtered, tempered, and recirculated back to the process.

The main components of the system—cutting head with cutting chamber, die plate, and start-up valve, all on a common supporting frame—are one major assembly. All the other system components, such as process-water circuit with bypass, cutting chamber discharge, sight glass, centrifugal dryer, belt filter, water pump, heat exchanger, and transport system can be selected from a comprehensive range of accessories and combined into a job-specific system.

In every underwater pelletizing system, a fragile temperature equilibrium exists within the cutting chamber and die plate. The die plate is both continuously cooled by the process water and heated by die-head heaters and the hot melt flow. Reducing the energy loss from the die plate to the process water results in a much more stable processing condition and increased product quality. In order to reduce this heat loss, the processor may choose a thermally insulating die plate and/or switch to a fluid-heated die.

SPECIFICATION

Model | Capacity | Motor | die head heating | water pump | Cutting knife adjustment |

kg/h | kw | kw | kw | ||

UW10 | 1~150 | 2.2 | 8 | 2.2 | manual |

UW30 | 100~400 | 4 | 8 | 4 | manual/pneumatic |

UW50 | 200~600 | 5.5 | 12 | 4 | manual/pneumatic |

UW80 | 400~1000 | 7.5 | 12 | 5.5 | manual/pneumatic |

UW200 | 1000~3000 | 11 | 15 or heat conduction oil | 5.5 | pneumatic/hydraulic |

UW500 | 2000~5000 | 15 | heat conduction oil | 7.5 | pneumatic/hydraulic |

UW1000 | 4000~10000 | 18.5 | heat conduction oil | 11 | pneumatic/hydraulic |

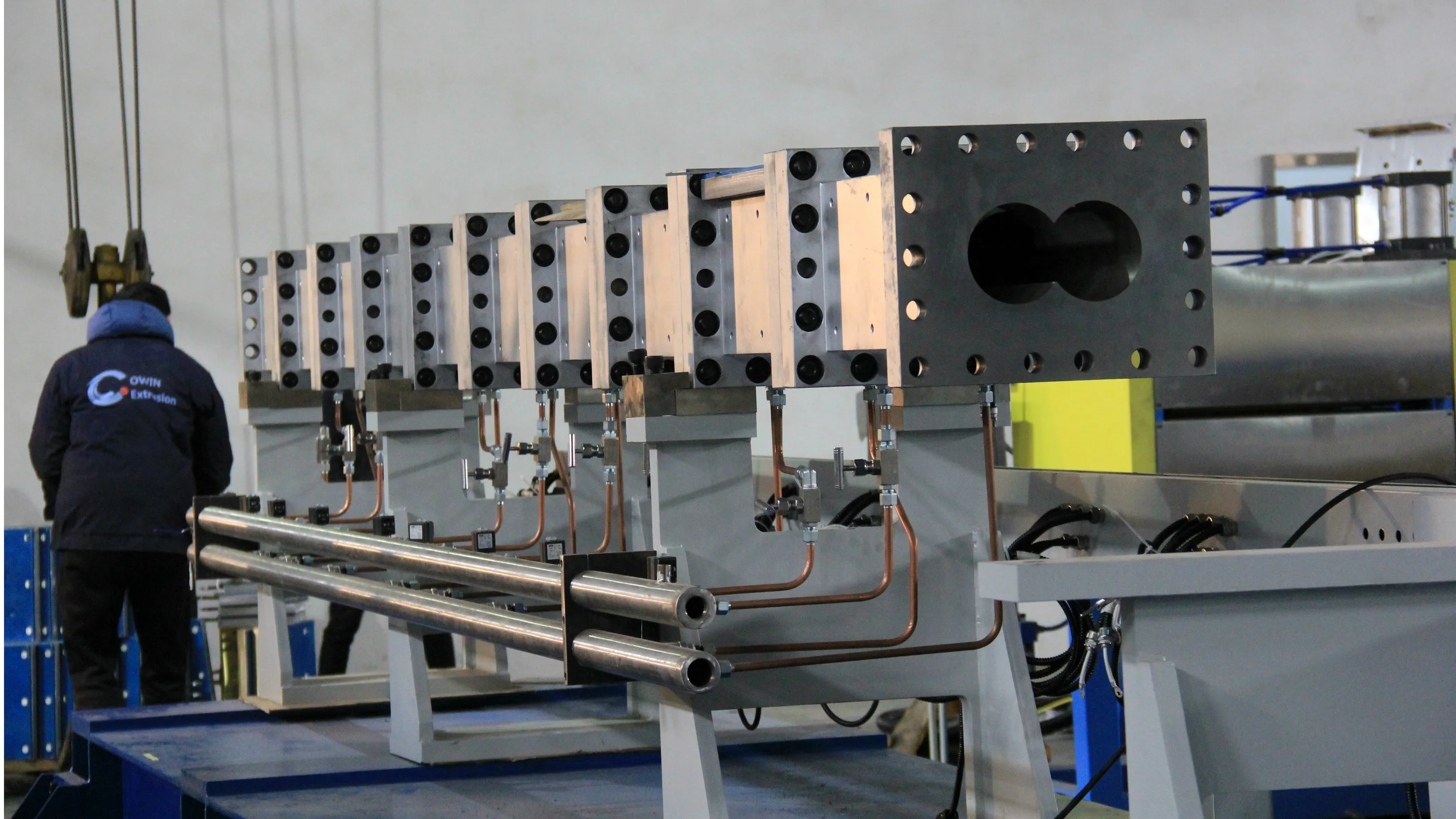

Company video and photos

| Business Type | Manufacturer, Trading Company | Main Products | twin screw extruder,single screw extruder,two stage extrudder,plastic granulator,plastic machinery parts |

| Total Employees | 51 - 100 People | Year Established | 2012 |

| Total Annual Revenue | US$10 Million - US$50 Million | ||

| Certifications | -- | Product Certifications | CE |

| Trademarks | -- | Patents | -- |

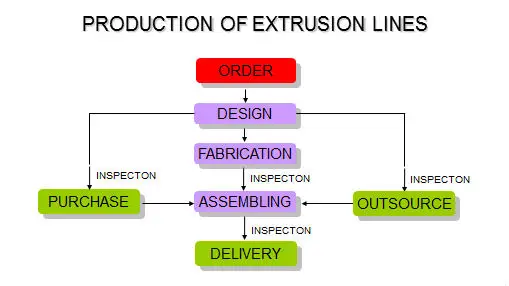

Production Flow

| machineName | yearsUsed | brandModel | quantity | condition | verified |

|---|---|---|---|---|---|

| CNC LATHE | 6140, 6150 | 2 | |||

| CNC SCREW LATHE | 6150 | 1 | |||

| CNC SCREW GRINDER | M1332A | 1 | |||

| VERTICAL MACHINING CENTER | 1060 | 1 | |||

| CYLINDRICAL GRINDER | M131 | 1 | |||

| SURFACE GRINDER | 7032 | 1 | |||

| VERTICAL MILLING MACHINE | XA5032A | 1 |